CASE STUDY – GEI-219 ERW tube milling

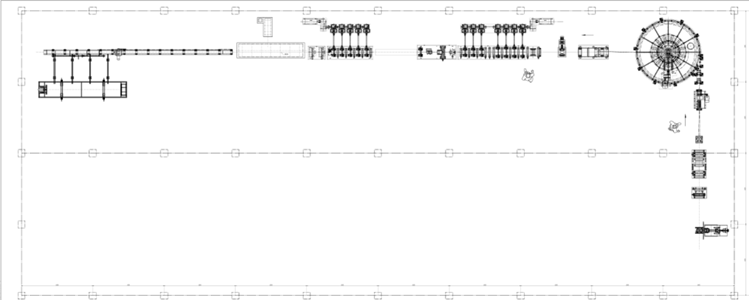

The GEI-219 ERW tube milling we export to Tunisia is adopts “W” forming methods, mainly produce diameterΦ219 round pipes. The working speed designed 30-50m/min. It mainly equipped double cone uncoiler, shear and butt-welder, horizontal spiral accumulator, forming and sizing unit, 600KW solid state HF, flying saw, power conveyor, and the forming rollers (1 group) .

Following is the layout of GEI-219 ERW tube mill equipment we designed:

This customer want to operate a new plant for manufacturing steel pipes under their local government support, so they find us to make a perfect solution for them. through continuous communication and discussion of technical specification and proposal and payment term, they come to our factory for visiting and disccussing details. they spoke highly of our company strength of designing and manuacturing. after that, our chief engineer also came to their plant for on site checking back and forth.

Finally, after seven month effort, we got the their trust and appoint as manufacturer to help them finish this project.

Whether the material choose or six months processing and assembly work. we do our best to ensure the quality and delivery in time.

Package and delivery to Tunisia

Customer factory foundation construction and after our customer had finished the workshop foundation, we will dispatch our engineers for instructing intallation and commission. also train them to work correctly use the machine to maximum raising production effiency. please keep attention to our update.