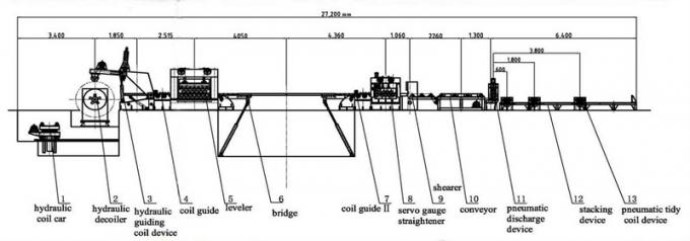

The cut to length line is a unit that divides the steel coil into single sheets and stacks them, generally with functions of uncoiling, straightening, measuring, cross-cutting to length and stacking. The whole line is controlled by PLC with computer display. GEIT can design and manufacture cut to length line according to customers requirement from range of materials thickness of 0.3-6mm and width of 150-2000m at max speed 60m/min. It highly automatic with features of good straightening effect, precising cutting, efficient production, reliable performance, easy operation and maintenance.

Work flow of cut to length line;

Coil car-----uncoiling---straightening ----shearing machine-----stacking and piling system

Brief introduction of cut to length line:

1. V shaped table

It is used to set the coil, to prevent from damaging the car due to putting the coil into car directly.

2. Hydraulic entry coil car

It consists of car base, wheel, bearing, axle, guide pillar, guide sleeve, upper bracket, rolling roller, hydraulic lifting oil cylinder, hydraulic motor and so on.

3. Hydraulic double head decoiler

It is equipped with guide rail type base (1200), a frame, uncoiler shaft,taper decoiler ,hydraulic opposite vertex device and the hydraulic brake wheel.

4. Press and pinch and shovel head device

It is composed of base, hydraulic pressure guiding device, hydraulic shovel head device, pinch and pre-leveling device and drive device.

5. Transition table

It is the working table which is composed of the rollers, frames and bearings, etc.

6. guide device

It is composed guide frame, flexible plate, guide adjust device, vertical-roller type side guide rollers.

7. Hydraulic roller device

It is composed of base, frame, square slide block, hydraulic lifting device, two rollers.

8. Straightener

It makes uneven steels even and guide them to the right following process.

9. PLC fixed length control device

It is composed of the code transition device , code control device and rotary coder.

10. Hydraulic cutter

shear model: cut from up to down hydraulically

11. Pendulum clamp to send machine

It is composed of the working table, frame, rollers and bearings, motor with up and down device etc.

12. run-out table

8m in length, it can make the end produce out of the production line.

13. Hydraulic system

Hydraulic system is the important composed part of the production line, it is the power supply of the line.

14. Pneumatic system

15. Electrical system

Next: Stainless steel pipe/tube making machine, stainless steel pipe/tube mill