Product Details

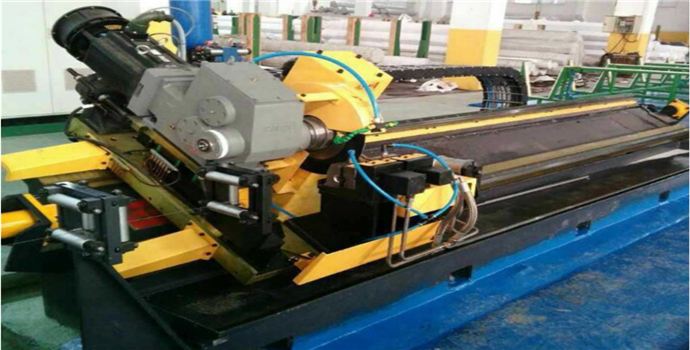

Saw is a necessary equipment in the whole tube making process, it can size and saw different shape and length of welded tube at a high speed. Generally, In ERW pipe mill, there are two choice for pipe cutting method, one is flying saw, other is cold saw. The both can be made by our company.

advantage of cold saw:

- The cutting section has high precision, no burr inside and outside, and the cutting surface is smooth , no need for subsequent processing such as end-facing and chamfering (reducing the processing strength of the next process), saving the process and raw materials;

- the pipes will not change due to the high temperature caused by friction.

- operator fatigue is low, improve sawing efficiency;

- sawing process without sparks, no dust, no noise;

- environmental protection and energy saving.

But because the cold saw input cost and maintenance cost is much higher than computer flying saw, therefore, the price and product quality requirement are the mainly factor in selection of cut method.

Flying saw

Cold saw

Flying saw test video:

Prev:

Working principle of horizontal spiral looper of welded pipe machine

Next: Spiral welded pipe machine

Next: Spiral welded pipe machine