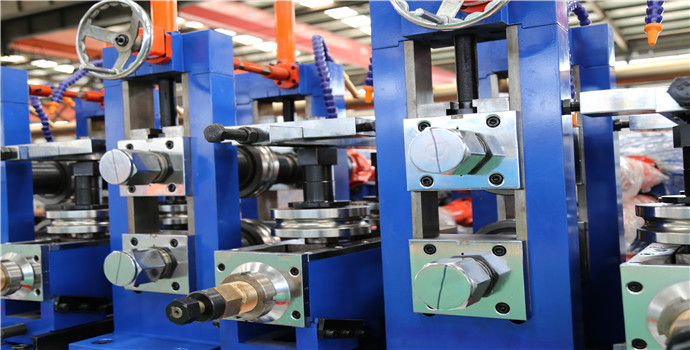

What is it GEI-89 steel tube mill? It is used to produce the steel pipe size of Φ48mm-89mm with thickness of 2.0-4.0mm at common speed of 50-90m/min. We can also chage the configuration to reach high speed according to individual requirement. The whole tube mill adopts “W” Forming process in the forming process with advantages of making the force more reasonable and the deformation of the material of each rack of the unit is more perfect.

The basic technical parameter of GEI-89 tube mill line as follow:

|

1 |

Mechanical property |

Yield strength(σs)≤275MPa |

|

2 |

Width of steel strip: |

150-280mm |

|

3 |

Thickness of steel strip: |

2.0-4.0mm |

|

4 |

I.D of steel coil: |

Φ480-Φ550mm |

|

5 |

O.D of steel coil: |

≤Φ1600mm |

|

6 |

Coil weight: |

≤3t |

|

7 |

Specification of tube: |

Φ48mm-89mm |

|

8 |

Length of tube: |

6m±3mm |

|

9 |

Total installed capacity: |

~ 630KW |

|

10 |

Speed of unit: |

50-90m/min |

|

11 |

Floor space: |

72*10m |

|

12 |

Overhead crane: |

5ton*2set |

|

13 |

Operation direction: |

Right feed(or according to customer required) |

Work process of GEI-89 tube mill machine

uncoiler → shear and butt-welder → Disc looper → Forming and sizing unit → flying saw → run-out table→ packing

The GEI-89 ERW tube mill usually equipped with double station uncoiler, shear and butt-welder, Disc looper, Forming and sizing machine, flying saw, 300KW HF welder, packer, hydraulic system and electric system etc single machines. If you are interest in begin this kind of project, please contact us for perfect technical proposal and quotations. We will design the most suitable tube mill according to your exact requirement.