Product Details

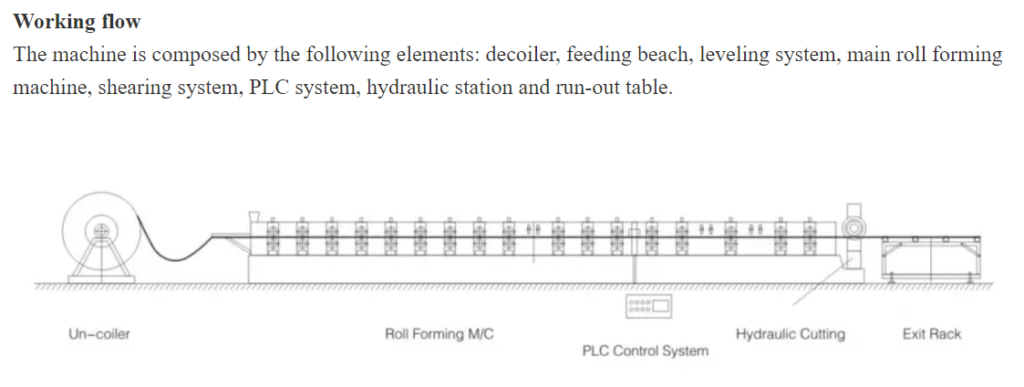

GEI-Shutter door roll forming machine

Our roller shutter door roll forming machine is customized, we can design and produce the roller shutter door roll forming machine as your profile drawing. Here I attached one our roller shutter door profile drawing for you reference, you can select the one you want and then let me know, we will produce the machine as the roller shutter door profile drawing you selected.

basic technical parameters:

|

1.Suitable material

|

Color steel sheet , galvanized steel sheet,aluminum sheet

|

|

2.Installation Dimension (L*W*H):

|

12000X1700X1500

|

|

3.Main motor power

|

5.5KW with Cycloidal reducer

|

|

4.Hydraulic station power

|

3KW

|

|

5. Hydraulic oil pump

|

40#

|

|

6.Thickness of material

|

0.8mm~1.2mm

|

|

7.Diameter of principal axis

|

Φ70-90mm

|

|

8.Material expand width

|

760mm

|

|

9.Electric tension

|

380V 3phase 50HZ or as the customer's requirements

|

|

10.Material of roller

|

High grade 45# forged steel plated with hard chrome plating

|

|

11.Controlling system

|

PLC

|

|

12.Processing speed

|

8-12m/min(glazed tile is 2-3m/min)

|

|

13.Processing precision within

|

1.00mm (depend on design)

|

|

14.Material of cutting blade

|

Cr12 mould steel with quenched treatment

|

|

15.Kind of drive

|

0.6 inch chain link bearing model 6210

|

|

16.Roller station

|

9-20 Rollers

|

|

17.Roller material

|

high grade 45#steel; Cr12 quenching

|

|

18. Leak frame load-bearing

|

4.6T

|

Prev:

What factors determine the price of stainless steel welded pipe unit?

Next: GEI-Double layer roll forming machine

Next: GEI-Double layer roll forming machine