GEI-32 ERW tube mill machine

GEI-32 ERW tube mill is intended for manufacturing of pipe diameter of Φ10mm-Φ32mm with thickness of 0.8mm–2.0mm from carbon steel, steel, low carbon steel and others.. the finish pipe type can be round pipe, square pipe, oval pipe and rectangle pipe. This tube mill machine adopts “W” Forming process in the forming process with advantages of making the force more reasonable and the deformation of the material of each rack of the unit is more perfect. The remarkable features of the whole unit is fast, efficient, time-saving, and labor-saving and the unit features is high strength and strong rigidity.

GEI-32 ERW tube machine basic technical parameters:

|

1 |

Mechanical property |

Yield strength(σs)≤275MPa |

|

2 |

Width of steel strip: |

55-100mm |

|

3 |

Thickness of steel strip: |

0.8-2mm |

|

4 |

I.D of steel coil: |

Φ480-Φ550mm |

|

5 |

O.D of steel coil: |

≤Φ1600mm |

|

6 |

Coil weight: |

≤1t |

|

7 |

Specification of tube: |

Φ10mm-32mm |

|

8 |

Length of tube: |

6m±3mm |

|

9 |

Total installed capacity: |

~ 280KW |

|

10 |

Speed of unit: |

60-150m/min |

|

11 |

Floor space: |

62*8m |

|

12 |

Overhead crane: |

5ton*2set |

|

13 |

Operation direction: |

Right feed(or according to customer required) |

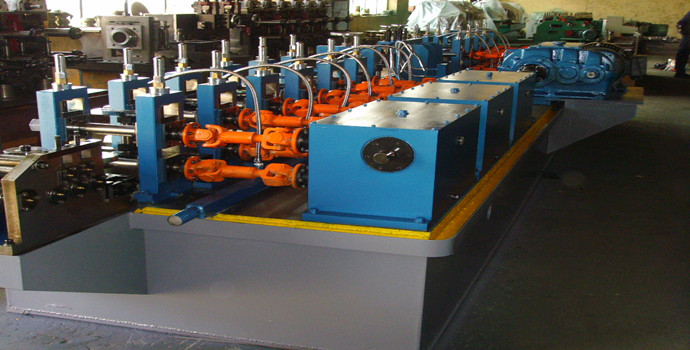

GEI-32 ERW tube machine work flow:

Double station uncoiler → Shear and butt-welder → Disc looper → Forming and sizing → Flying saw → run-out table → packer

GEI-32 Tube mill consists of following items:

GEI-32 Tube mill consists of following items:

|

No. |

Items |

|

1 |

Double station Uncoiler |

|

2 |

Shear and butt-welder |

|

3 |

Disc looper |

|

4 |

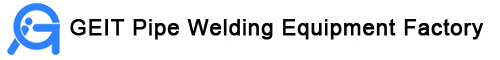

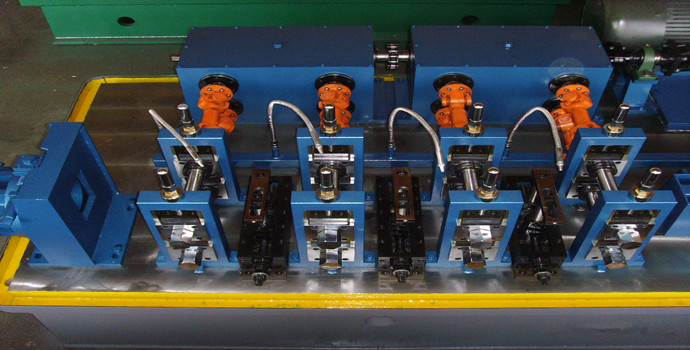

Forming and sizing unit |

|

5 |

Computer flying saw |

|

6 |

Run-out table |

|

7 |

packer |

|

8 |

Auxiliary hydraulic station |

|

9 |

Auxiliary electric control |

|

10 |

150KW solid state HF |

|

11 |

anchor bolt, embedded iron and wedged pad iron |

|

12 |

Rolling bearing |

|

13 |

Shear and butt-welder electrical welding machine |

|

14 |

Special tools along machine |

|

15 |

Saw blade |

|

16 |

Scraper tool bit |

|

17 |

magnetic bar |

|

18 |

induction coil |

|

19 |

spare parts |

Next: GEI-219 straight seam welded steel pipe mill machine